INTRODUCTION

Edible mushrooms are an important food group that has both high nutrient and medicinal values. Paddy straw mushrooms, Volvariella volvacea (Bull. ex F.) Singer, contain high contents of minerals, protein (28.1%), polysaccharides (5.8%), fiber (20.7%), and carbohydrate (29.6%), but little fat or cholesterol [1,2]. They are also an excellent source of bioactive mycochemicals such as terpenes, polypeptides, steroids, and phenolic compounds and effective antioxidant enzymes that contribute to their significant antioxidant properties [2,3]. Consequently, they are associated with several health benefits, including cancer prevention, antimicrobial activity, hypotensive, hepatoprotective, anti-ageing, and antihyperlipidemic effects [2,4]. Due to their nutrient value and pleasant taste, the paddy straw mushroom is reported to be the sixth most important cultivated edible mushroom in the world [2]. The climate condition in the North of Vietnam is conducive to the cultivation of this mushroom and its production in this area provides extra income for local poor farmers, contributing to poverty reduction [5].

It is clear that mushroom cultivation is widespread and important. This is particularly so in low- and lower-middle-income countries where the nutrition of mushrooms and the contribution to the farming family economy is particularly important. The paddy straw mushroom is particularly important in both of these respects. Improving the yield/efficiency of paddy straw mushroom propagation could therefore have a big impact. As the globe moves to a sustainable economy, a move to the re-use of waste materials in the circular economy is increasingly necessary. Whilst paddy straw mushrooms are widely propagated on waste materials such as rice straw, waste cotton, water hyacinth, waste sugar cane, waste maize and oil palm free-fruit bunch [6-8], the use of spent oyster mushroom compost is another possible waste material that could be effectively reused rather than wasted. It reported that spent mushroom sawdust can be used to cultivate this mushroom [9], proving a useful second use for an otherwise waste product.

In Vietnam, oyster and other edible/medicinal mushroom cultivation is popular and is adaptable to climate change [10]. Consequently, sources of spent mushroom sawdust are abundant. Spent oyster mushroom sawdust contains high macronutrients of nitrogen, phosphorus, and potassium [11,12]. This substrate has a ratio of C/N ca. 70, much lower than that of fresh sawdust (ratio of C/N ca. 192) [13]. Bui Dang Khoa et al. [9] found that the biological efficiency of paddy straw mushrooms cultivated on 100% spent oyster mushroom sawdust, 100% spent oyster mushroom sawdust supplemented the mix of 0.5 % rice bran and 0.5% corn bran, and the mix of 75% spent oyster mushroom sawdust and 25% rice straw with supplementing 0.5% rice bran and 0.5% corn bran under the circular compact bed and indoor conditions were 5.5, 13.1, and 15.4%, respectively.

Besides the composition of substrate and type of supplements, the yield of paddy straw mushrooms has been affected by many other factors such as season, bedding technology, and indoor or outdoor cultivation conditions [6,9,14]. Traditionally, paddy straw mushroom propagation in Vietnam is in hand-made beds and under outdoor conditions; thus, the yield of paddy straw mushrooms is not stable due to the influence of several environmental factors. Consequently, the present study investigates how spent oyster mushroom compost can be most effectively used by small farmers, testing indoor verse outdoor cultivation and comparing conventionally constructive mushroom propagation beds against a promising new form of bed construction.

MATERIALS

The preparation of the bed material followed the method described by Bui Dang Khoa et al. [9]. Good quality spent mushroom sawdust (SMS) or rice straw (RS) was soaked in water containing 3% w/v CaCO3 and stacked in the size of 1.2 m × 1.2 m × 0.8 m (L × W × H) for SMS and 1.2 m × 1.2 m × 1.2 m (L × W × H) for RS. The stacks of material were covered with PVC tarpaulin and left for 7 days and 14 days, for SMS and RS respectively, to mature and to eliminate contaminating microorganisms. Turning of the stacked material was conducted every 3 days in order to ensure that the material was thoroughly mixed and that there was an even moisture content throughout the stack.

The commercial rice-straw spawn of Volvariella volvacea was obtained from a commercial supplier (Than Nong Co. Ltd, Can Tho City, Viet Nam). The ratio of spawn to compost substrate weight used in the present study was 0.8%.

METHODS

Experimental set-up

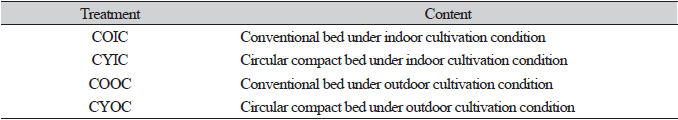

The best experimental treatment reported in a study by Bui et al. [9] was the mix of 75% spent oyster mushroom sawdust and 25% rice straw, supplemented with 0.5% rice bran and 0.5% corn bran. This had the highest biological efficiency of 15.4%. Consequently, this growth media was used in the present study. Consequently, a two-level factorial experiment was conducted in order to assess the effect of cultivation technology, i.e., bed methods (conventional bed and circular compact bed) under indoor or outdoor conditions on the yield of paddy straw mushrooms (Table 1).

The two different bed methods are as follows:

1. Conventional bed: bedding in rows consisting of three substrate layers and two spawn layers, 40 cm in width, 15 cm in height.

2. Circular compact bed: three substrate layers and two spawn layers, 60 cm diameter, 45 cm in height.

Both conventional bed and circular compact bed were prepared using the well-mixed substrate consisting of a 3:1 ratio (based on volume) of composting spent oyster mushroom sawdust (12.5 kg dry weight) and 25% composting rice straw (2.1 kg dry weight). Paddy straw spawn was added at a rate of 0.8% composting substrate based on the material weight and 0.5% rice bran and 0.5% corn bran were mixed with the spawn bits. Each treatment was replicated three times.

The bed temperatures were recorded from day 1 to day 13 after planting once per two days at 3 different locations including 1 location on the surface of the beds and 2 locations on both sides of the bed. Observations on the days for the beginning observed spawn run (DFSR), days for pin head formation (DFPF), days for button formation (DFBF), days for egg-shaped formation (DFEF), yield parameters in relation to the average button weight of the first 30 fruit bodies, the average number of fruit bodies/bed and biological efficiency (B.E.).

Biological efficiency (%) =  ×100%

×100%

Noticeably, a frame of bamboo wicker 60 cm in diameter and 45 cm in height was used to make the circular compact bed with a bamboo pole (diameter 3.4 cm, length 1.0 m) in the middle of each circular bed for ventilation and good drainage. After 1 day, the bamboo woven frame will be removed and the surface of all treatments, including both circular compact beds and conventional beds will be covered with a thin layer of rice straw to keep the temperature and humidity of the beds. Fruit bodies in the experiment were collected within 30 days since harvesting the first fruit body and were collected twice a day in the early morning or late afternoon.

Caring: Moisture of conventional beds and circular compact beds was maintained at 65-70% by fresh watering. Conditions of coconut leaf house were kept at 30-32℃, light 600 lux, humidity 80-90%, and air ventilation.

Statistical analysis

A two-way ANOVA in SPSS vs. 22 was conducted for all statistical analyses in this study to find differences in the impacts of bed method and cultivation condition on the yield of paddy straw mushrooms. However, one-way ANOVA was used to analyse the differences in the temperature of the treatments.

RESULTS

Effects of bed type and cultivation condition on changes in bed temperatures

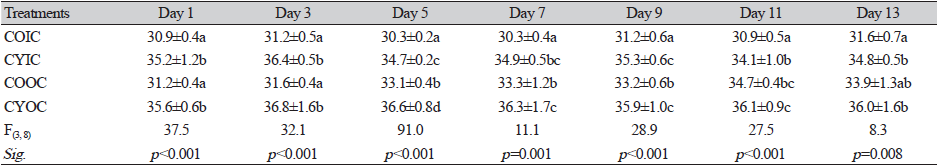

There were big differences in the temperatures of the treatments during the first 13 days of the cultivation period (Table 2). In general, the temperatures of circular compact beds under both indoor and outdoor conditions were greatly higher than that of conventional beds in all the investigated time. Also, the highest bed temperatures were observed in the circular compact bed under outdoor cultivation conditions treatment. However, the bed temperatures of the conventional beds under outdoor cultivation conditions treatment had the strongest increases in the first 11 days of the incubation process compared to the remaining treatments.

In general, statistical analysis showed that the temperatures of the treatments in circular compact beds under both outdoor and indoor conditions were not significantly different from each other, except on day 5 and day 7. However, they were significantly different from that of the treatments in conventional beds under indoor conditions during the first 13 days of the cultivation period.

Effects of bed type and cultivation condition on different growth stages of paddy straw mushrooms

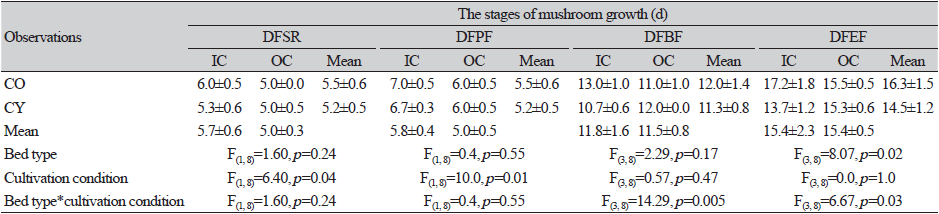

In general, the paddy straw mushroom showed different responses in terms of distinct growth stages to bed type and cultivation. The growth time in the conventional bed cultivated indoor treatment was the longest in all paddy straw mushroom growth stages (Table 3). The mean number of days for the observed beginning of spawn run (DFSR) was relatively similar in all treatments (Table 3). This was confirmed by a one-way ANOVA analysis, which showed there were no significant differences in DFSR among the treatments. However, two-way ANOVA analysis showed cultivation condition had a significant effect on DFSR (F (1, 8)=6.40, p=0.04), but bed type did not (F (1, 8)=1.60, p=0.24). Consequently, no interaction effect between bed type and cultivation conditions was found, indicating that there was no difference in the effect of bed type on the DFSR by cultivation condition. Similarly, the same tendency was observed for the time taken to reach pin head formation (DFPF; Table 3).

The number of days required for button formation (DFBF) was highest under conventional bed indoor conditions compared to the other treatments, but no significant main effects were found for bed type and cultivation conditions in the two-way ANOVA. The interaction term was significant, however (Table 3). This is explained by a crossover interaction in which DFBF was reached more slowly under indoor conditions in the conventional bed, but the opposite was the case for the circular compact bed.

Larger differences in the effects of bed type on the cultivation of the mushrooms were found for the development of the egg-shaped formation (DFEF). DFEF in the conventional bed cultivated indoor treatment was appreciable longer than that in the circular compact bed cultivated indoor treatment at 17.2 days compared to 13.7 days in the conventional bed cultivated outdoor treatment. The two bed types had similar development times under outdoor conditions at 15.5 days compared to 15.3 days for the conventional and circular beds respectively (Table 3). Consequently, a significant main effect of bed type on the DFEF was shown in the statistical analysis, but the main effect of cultivation conditions on the DFEF was non-significant. The interaction term between bed type and cultivation condition was also significant (F (3, 8)=6.67, p=0.03), indicating there was a difference in the effect of bed type on the DFEF by cultivation condition.

Effect of bed type and cultivation condition on paddy straw mushroom yield factors.

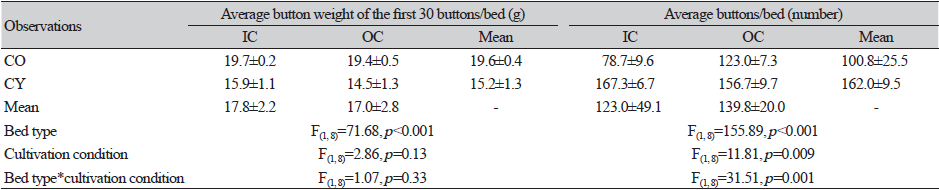

There were fluctuations in the average weight of the first 30 buttons/bed and the total number of buttons/bed. Although the button weights of the first 30 buttons were overwhelmingly higher in the conventional bed type under both indoor and outdoor conditions compared to the circular compact bed type under the same cultivation conditions (Table 4). The highest average button weight of the first 30 buttons/bed was found in the conventional bed indoor conditions treatment (19.7±0.2 g), but the total number of mushroom buttons harvested was higher in the circular bed indoor conditions treatment (167.3±6.7 buttons/bed) than other.

Subsequent statistical analysis of the data demonstrated that bed type significantly affected the mean button weight of the first 30 buttons/bed and the total number of buttons/bed of paddy straw mushroom harvested, but the cultivation condition factor was not (F (1, 8)=71.68, p<0.001 and F (1, 8)=2.86, p=0.13, respectively for bed type and cultivation condition). However, both bed type and cultivation condition factors had significant effects on the number of buttons/bed (F (1, 8)=155.89, p<0.001 and F (1, 8)=11.81, p=0.009, respectively for bed type and cultivation condition). Furthermore, interaction effects between bed type and cultivation condition on the mean button weight of the first 30 buttons/bed and the total number of buttons/bed of paddy straw mushroom were also significant (F (1, 8)=1.07, p=0.33 and F (1, 8)=31.51, p=0.001, respectively for bed type and cultivation condition), indicating there were differences in effects of bed type by cultivation condition on both parameters.

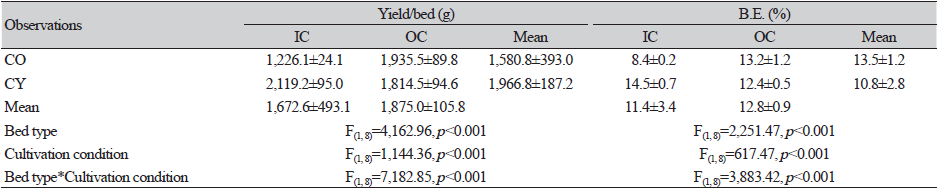

In terms of the yield of paddy straw mushrooms, a higher yield was obtained under outdoor conditions (1875.0±105.8 g/bed compared to 1672.6±493.1 g/bed, for outdoor and indoor conditions respectively). However, the mushroom yield in the conventional bed treatments (1580.8±393.0 g/bed) was much lower than that in the circular compact treatments (1966.8±187.2 g/bed). Consequently, the biological efficiencies of outdoor cultivation and circular compact bed treatment were higher than that of indoor cultivation and conventional bed treatments (Table 5; Figs. 1 and 2).

The experimental results also showed that the highest paddy straw mushroom yield and B.E. was achieved in the circular compact bed under indoor cultivation conditions with 2119.2±95.0 g/bed and 14.5±0.7%. Conversely, the lowest mushroom yield and B.E. occurred in the conventional bed under indoor cultivation condition with 1226.1±24.1 g/bed and 8.4±0.2 %, respectively. The mushroom yield and B.E. in the circular bed indoor condition treatment differed significantly from that of the conventional bed indoor conditions treatment but did not differ significantly from that in the conventional bed under outdoor cultivation condition.

Two-way ANOVA analysis proved that both bed type and cultivation condition factors had significant influences on the yield and B.E. of paddy straw mushrooms (Table 5). Consequently, interaction effects between bed type and cultivation condition on yield and B.E. were found (F (1, 8)=7,182.85, p<0.001 and F (1, 8)=3,883.42, p<0.001, respectively), indicating there were differences in effects of bed type on the mushroom yield and B.E. by cultivation condition.

DISCUSSION

Effects of bed type and cultivation condition on changes in bed temperatures

In general, the temperatures of circular compact beds were higher than that of conventional beds during the first 13 d of the cultivation period. Normally, the temperature of circular compact beds was higher than 35℃. This can be explained by the lower height of the conventional beds compared to the circular compact bed, which reduced the ability to retain heat in the conventional bed type. In addition, under indoor conditions, mushroom beds were not warmed by sunlight, thus the bed temperature was low. The proper temperature for mycelium growth is from 30 to 35℃ [15] and the temperature of fruit body formation can oscillate from 28 to 38℃ [16]. Therefore, the bed temperature of all treatments was appropriate for the mushroom growth and the formation of fruit bodies.

Effect of bed type and cultivation condition on paddy straw mushroom yield factors.

There are several cultivation methods used to cultivate paddy straw mushrooms [6,9,15]. Also, the traditional methods of paddy straw cultivation vary between different regions and countries. The cultivation method used in the present study represent the conventional methods used in the south of Vietnam and a potentially new method.

In this present study, wide variations in the factors related to the yield of the paddy straw mushroom, Volvariella volvacea, were shown with different bed types and cultivation conditions affecting yield. As described above the suitable bed temperature for mushroom growth fluctuates from 30 to 35℃ [15]. However, in the present study, mushroom growth in treatments with beds achieving temperatures above 33℃ (namely circular compact beds under both indoor and outdoor conditions and conventional beds under outdoor conditions), reached the different growth stages DFSR, DFPF, DFBF, and DFEF (Tables 2 and 3) in a shorter time. Furthermore, the number of average buttons/bed in circular compact beds was more than that in conventional beds, despite the lighter button weight of the first 30 buttons/bed (Table 4). Thiribhuvanamala et al. [6] also found that the number of average buttons/bed was highest in circular compact beds compared to other bed types, confirming that this type of bed is a more efficient way to produce paddy straw mushrooms.

In addition to temperature, the highest yield and B.E. of V. volvacea in this present study may be contributed by other physical factors such as compactness and wetness of the beds [6]. Circular compact beds in this present study had a better ability to retain heat and wetness than the conventional bed type. However, the conventional bed under outdoor conditions treatments achieved the second-highest yield and B.E. (1,935.5±89.8 g/bed and 13.2±1.2%, respectively). This may be due to the warming effect of sunlight on the conventional beds; thus, the yield factors were improved.

In summary, physical factors, particularly bed temperature, play a crucial role in increasing the yield of paddy straw mushrooms. Once the mushrooms are harvested, the growth medium can also be used as an organic fertilizer in order to improve the soil; hence, it will contribute to minimizing the negative impact of the mushroom industry on the quality of the living environment [10].

CONCLUSION

Spent oyster mushroom sawdust is an appropriate medium on which to grow paddy straw mushrooms in both indoor and outdoor conditions, demonstrating a further use for a by-product that would otherwise go to waste. Under the indoor condition, the circular compact bed treatments had the highest yield and B.E. with 2,119.2 g/bed and a B.E, of 14.5%, whilst the conventional bed treatments had the lowest yield at 1,226.1 g/bed and B.E. 8.4%. Under indoor conditions, the circular compact bed treatment also had a high yield and B.E. with 1,935.5 g/bed and 13.2%, respectively. Whilst paddy straw mushroom cultivated on spent oyster mushroom sawdust could be propagated under both outdoor and indoor conditions by conventional and circular compact methods, the results of the present study suggest that the best yields can be obtained from indoor propagation using circular compact beds rather than conventional beds.